Hi,

this week I discussed and settled with the Track Manufacturing team that they will be handling the bends of the track's corners (which they have completed). I completed most of the PowerPoint and started the final report. The final report first draft is due on Friday, so we will continue to work on it throughout this week. I have been e-mailing Eric, Michael, and Neil the bill of materials which we have completed for the most urgent material we needed: PLA filament. Eric approved of it and we purchased it for only $93 on Amazon which should be enough material for all 30 castings of our U-bracket. The bill of materials I completed was rather sloppy since we needed the PLA filament ASAP, but I will be updating it with all of the company's quotes tonight. This week was slightly more relaxing since it was Thanksgiving weekend and we were waiting for approvals.

Tuesday, November 29, 2016

Tuesday, November 22, 2016

11/23/2016 Blog #12

Hi,

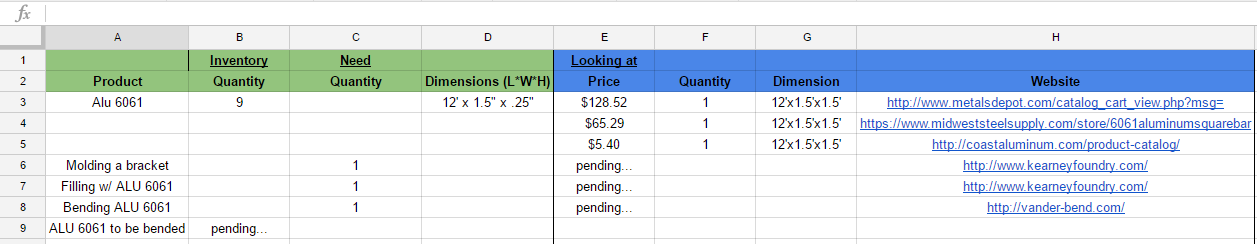

this week I was responsible for finishing a rather urgent Bill of Materials which I did and e-mailed to the three people: Eric Hagstrom, Michael Kemp, and Neil Shankar. They are responsible for approving our budget which will then need to be approved by the A.S. It was an urgent bill of materials because we decided to 3D print all of our brackets which our teammate Jezreel has offered to do for us, free of charge (of course, not including the 3 orders of PLA filament which would cost around $75). I also dimensioned the overall dimensions of the track to make sure it fit the given area when presenting at Paseo Prototyping and Maker's Faire which was within a 15 by 15 feet area. Our track currently sits at about 13 by 13 feet as shown below. On Friday, Jez and I went to see VanderBend to talk about our quote and future meet-ups and were given a tour. Having gone to VanderBend, we got to see how they do things different from us and we were given a little information as to how the track manufacturing team and us should tackle the bending issue.

this week I was responsible for finishing a rather urgent Bill of Materials which I did and e-mailed to the three people: Eric Hagstrom, Michael Kemp, and Neil Shankar. They are responsible for approving our budget which will then need to be approved by the A.S. It was an urgent bill of materials because we decided to 3D print all of our brackets which our teammate Jezreel has offered to do for us, free of charge (of course, not including the 3 orders of PLA filament which would cost around $75). I also dimensioned the overall dimensions of the track to make sure it fit the given area when presenting at Paseo Prototyping and Maker's Faire which was within a 15 by 15 feet area. Our track currently sits at about 13 by 13 feet as shown below. On Friday, Jez and I went to see VanderBend to talk about our quote and future meet-ups and were given a tour. Having gone to VanderBend, we got to see how they do things different from us and we were given a little information as to how the track manufacturing team and us should tackle the bending issue.

Tuesday, November 15, 2016

11/16/2016 Blog #11

Hi,

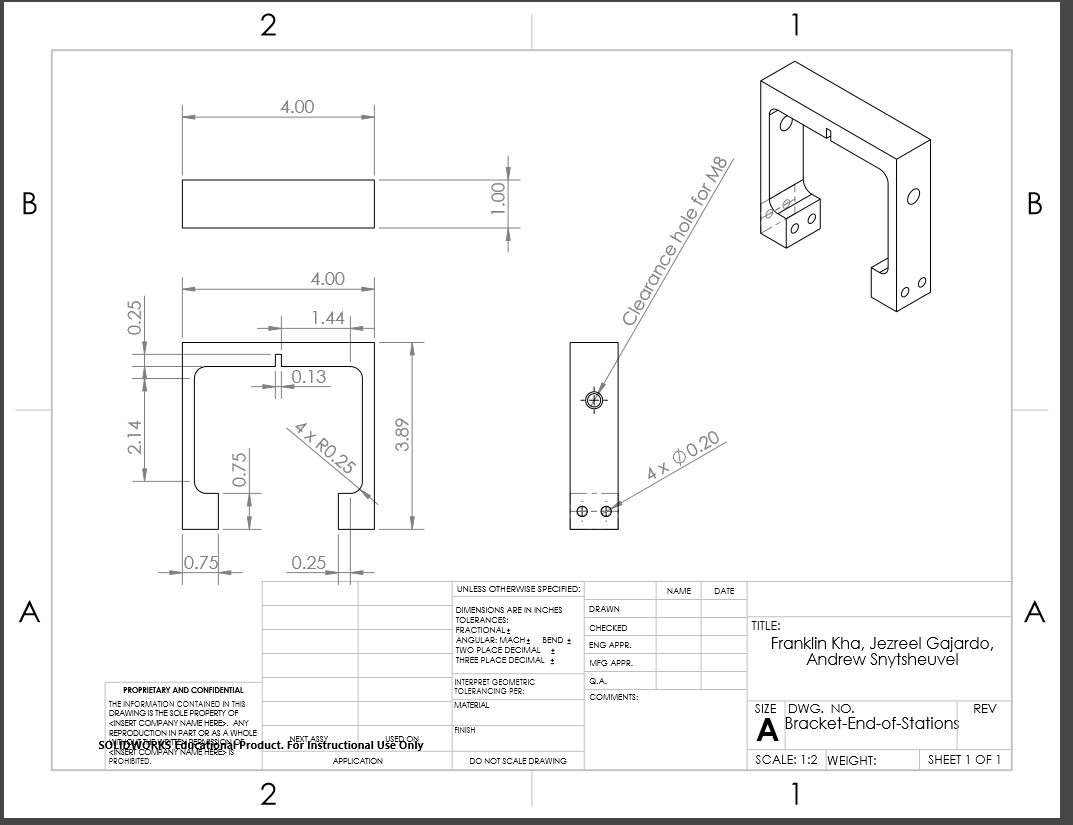

this week I have been remaining in contact with Kearny Foundry and about making a mold for our bracket (picture shown below). The only problem with the mold is that they would be unable to create the press fit and holes of the bracket (which would require for us to machine ourselves). I spoke with Kevin (from the manufacturing team) and we could make a station and/or mount to repeatedly tap holes and make the press fits consistently. Just this morning, however, I finally obtained a quote from them and they said: $940 for the mold and $16.30 per heat treated casting which totals $1429 and would take about four weeks. I told this to the group and we decided that we might just 3D print the brackets instead with a 60% ink fill PLA filament approximating $60 and roughly three weeks. 3D printing would save time, money, and solve the issue of creating repeatable press fits and holes.

this week I have been remaining in contact with Kearny Foundry and about making a mold for our bracket (picture shown below). The only problem with the mold is that they would be unable to create the press fit and holes of the bracket (which would require for us to machine ourselves). I spoke with Kevin (from the manufacturing team) and we could make a station and/or mount to repeatedly tap holes and make the press fits consistently. Just this morning, however, I finally obtained a quote from them and they said: $940 for the mold and $16.30 per heat treated casting which totals $1429 and would take about four weeks. I told this to the group and we decided that we might just 3D print the brackets instead with a 60% ink fill PLA filament approximating $60 and roughly three weeks. 3D printing would save time, money, and solve the issue of creating repeatable press fits and holes.

Tuesday, November 8, 2016

11/9/2016 Blog #10

Hi,

this week I focused on turning all SolidWorks parts into drawings and pdfs for the sake of organization, submitting to companies to request for quotes, and uploading to Google Drive for other teams to stay updated. Two of the fifteen drawings I finished this week are shown below. I was also responsible for getting a quote from Kearny Foundry; we should have a quote by next week just in time for the Bill of Materials deadline. We are slightly behind in terms of getting a quote because they had a ton of questions and since it was my first time asking for a quote, my e-mail was not extensive enough and I have been e-mailing Kearny for several weeks as a result. I have also been talking to Kevin from the 12th scale Track Manufacturing team about their process of creating a tool to bend aluminum and his team has been making great progress. We might just be able to manufacture all of the stuff in-house if the dimensions remain consistent.

this week I focused on turning all SolidWorks parts into drawings and pdfs for the sake of organization, submitting to companies to request for quotes, and uploading to Google Drive for other teams to stay updated. Two of the fifteen drawings I finished this week are shown below. I was also responsible for getting a quote from Kearny Foundry; we should have a quote by next week just in time for the Bill of Materials deadline. We are slightly behind in terms of getting a quote because they had a ton of questions and since it was my first time asking for a quote, my e-mail was not extensive enough and I have been e-mailing Kearny for several weeks as a result. I have also been talking to Kevin from the 12th scale Track Manufacturing team about their process of creating a tool to bend aluminum and his team has been making great progress. We might just be able to manufacture all of the stuff in-house if the dimensions remain consistent.

Franklin Kha

Tuesday, November 1, 2016

11/2/2016 Blog #9

Hi,

this week I did not do much after our Presentation. I have simply been shooting e-mails back and forth with Kearny Foundry, trying to satisfy their questions for us so we can get a quote - so, yes we are still waiting for a quote. We need to speak with the other teams about a more definitive date for all going to Vander-Bend together. There is little left to do in the design process; we are all figuring out manufacturing process currently. This week has been a busy week for me due to midterms and other projects.

this week I did not do much after our Presentation. I have simply been shooting e-mails back and forth with Kearny Foundry, trying to satisfy their questions for us so we can get a quote - so, yes we are still waiting for a quote. We need to speak with the other teams about a more definitive date for all going to Vander-Bend together. There is little left to do in the design process; we are all figuring out manufacturing process currently. This week has been a busy week for me due to midterms and other projects.

Tuesday, October 25, 2016

10/26/2016 Blog #8

Hi,

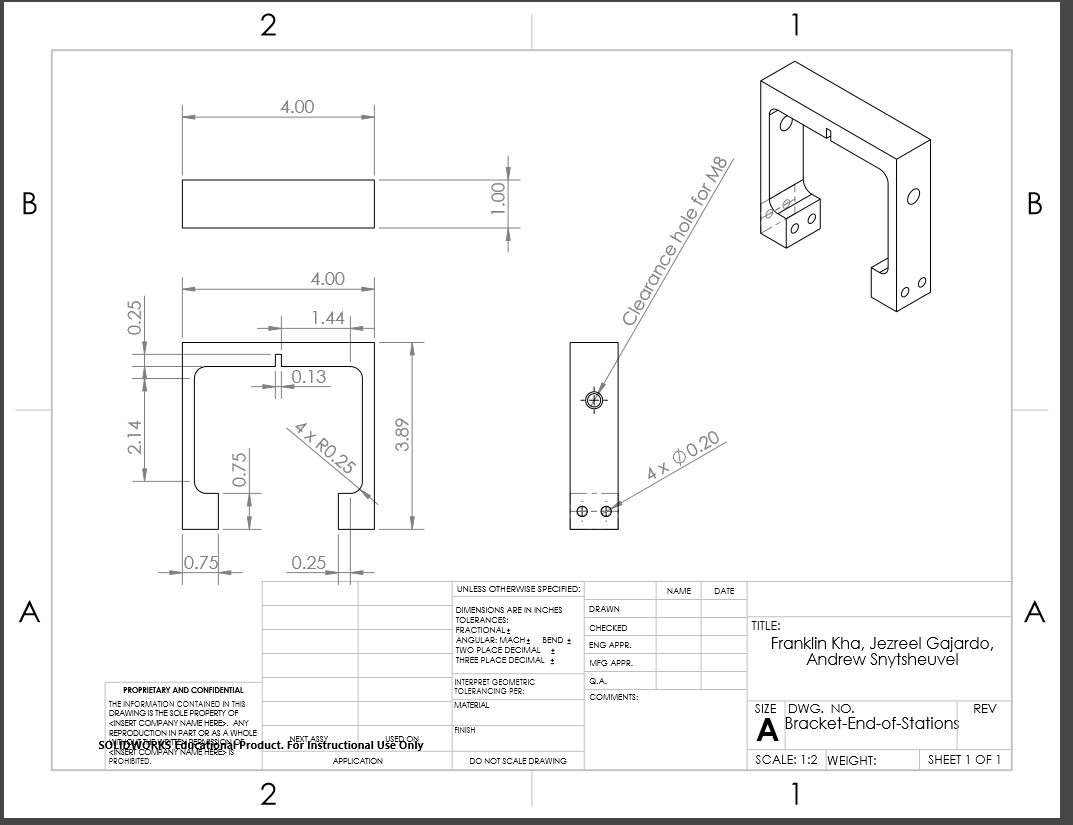

this week I drew the design that I sent to Kearny Foundry and requested a quote. I was trying to do Finite Element Analysis (FEA) on the track but it would not work since the entire loop was created as an assembly and our SolidWorks did not support that so I simply redrew the loop as one part to get an FEA for it. I also worked on the PowerPoint for Presentation #2 and created a spreadsheet to tabulate our inventory and things we might need. Afterward, I searched for several sites that would sell ALU 6061 and found that Eric's recommended company, Coast Aluminum, was the cheapest.

this week I drew the design that I sent to Kearny Foundry and requested a quote. I was trying to do Finite Element Analysis (FEA) on the track but it would not work since the entire loop was created as an assembly and our SolidWorks did not support that so I simply redrew the loop as one part to get an FEA for it. I also worked on the PowerPoint for Presentation #2 and created a spreadsheet to tabulate our inventory and things we might need. Afterward, I searched for several sites that would sell ALU 6061 and found that Eric's recommended company, Coast Aluminum, was the cheapest.

Tuesday, October 18, 2016

10/19/2016 Blog #7

Hi,

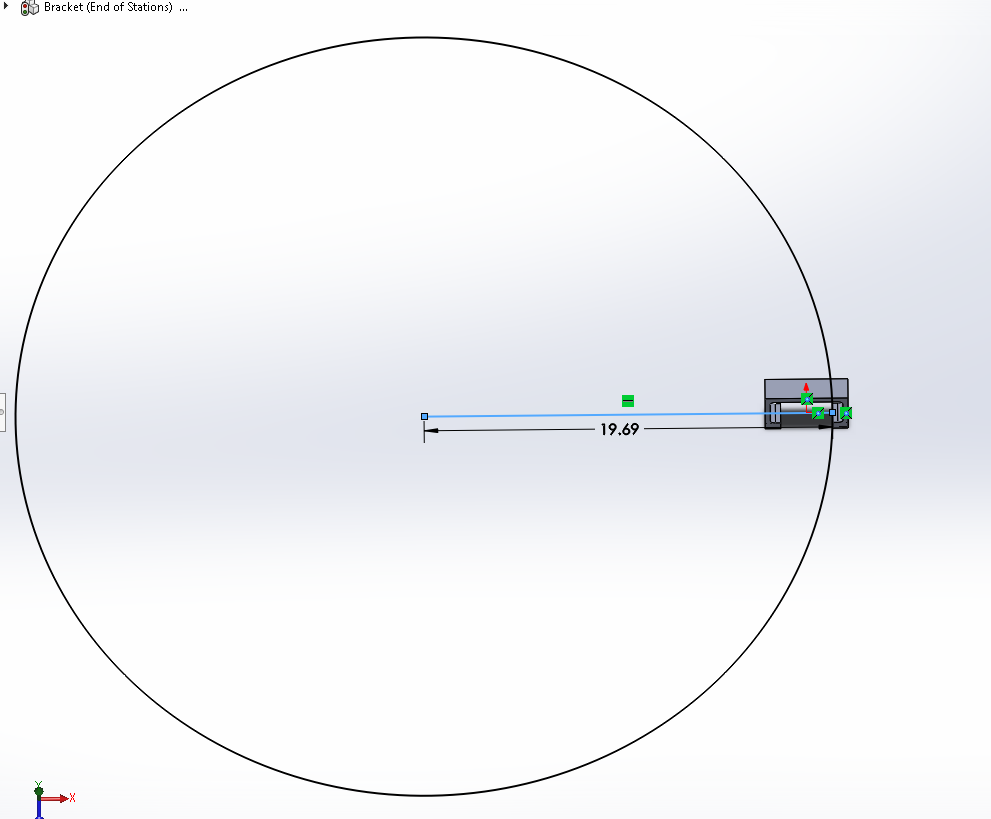

This week, I helped draft a bracket mount that would be specific to the curved track, but soon realized that the radius was so much larger that the curve on the bracket mount would be meaningless and costly. The picture below demonstrates the radius of the loop on the track and the mount with specific legs would align perfectly with the bend to reduce wiggle. However, as can be seen in the picture, the radius is so large that the tangential point of contact is negligible. It would take money to put in that extra radius that effectively accomplishes little. Next, I was also helping Jez change the units of the entire track from metric to standard since we wanted to make the numbers look good with a perfect three significant digit number. However, the dimensions of the track would change and we would have to build a new track, so we agreed to just change the units and leave as is for now until we begin working on the new track next semester. I also compiled a list of things that we will be addressing tomorrow before the presentation on the 26th of October, including, but not limited to, drafting a bill of materials, documenting inventory, contacting companies like Vander-Bend Manufacturing, performing FEA on our assembly, updating Gantt Chart, and creating a PowerPoint.

Franklin Kha

This week, I helped draft a bracket mount that would be specific to the curved track, but soon realized that the radius was so much larger that the curve on the bracket mount would be meaningless and costly. The picture below demonstrates the radius of the loop on the track and the mount with specific legs would align perfectly with the bend to reduce wiggle. However, as can be seen in the picture, the radius is so large that the tangential point of contact is negligible. It would take money to put in that extra radius that effectively accomplishes little. Next, I was also helping Jez change the units of the entire track from metric to standard since we wanted to make the numbers look good with a perfect three significant digit number. However, the dimensions of the track would change and we would have to build a new track, so we agreed to just change the units and leave as is for now until we begin working on the new track next semester. I also compiled a list of things that we will be addressing tomorrow before the presentation on the 26th of October, including, but not limited to, drafting a bill of materials, documenting inventory, contacting companies like Vander-Bend Manufacturing, performing FEA on our assembly, updating Gantt Chart, and creating a PowerPoint.

Franklin Kha

Subscribe to:

Posts (Atom)