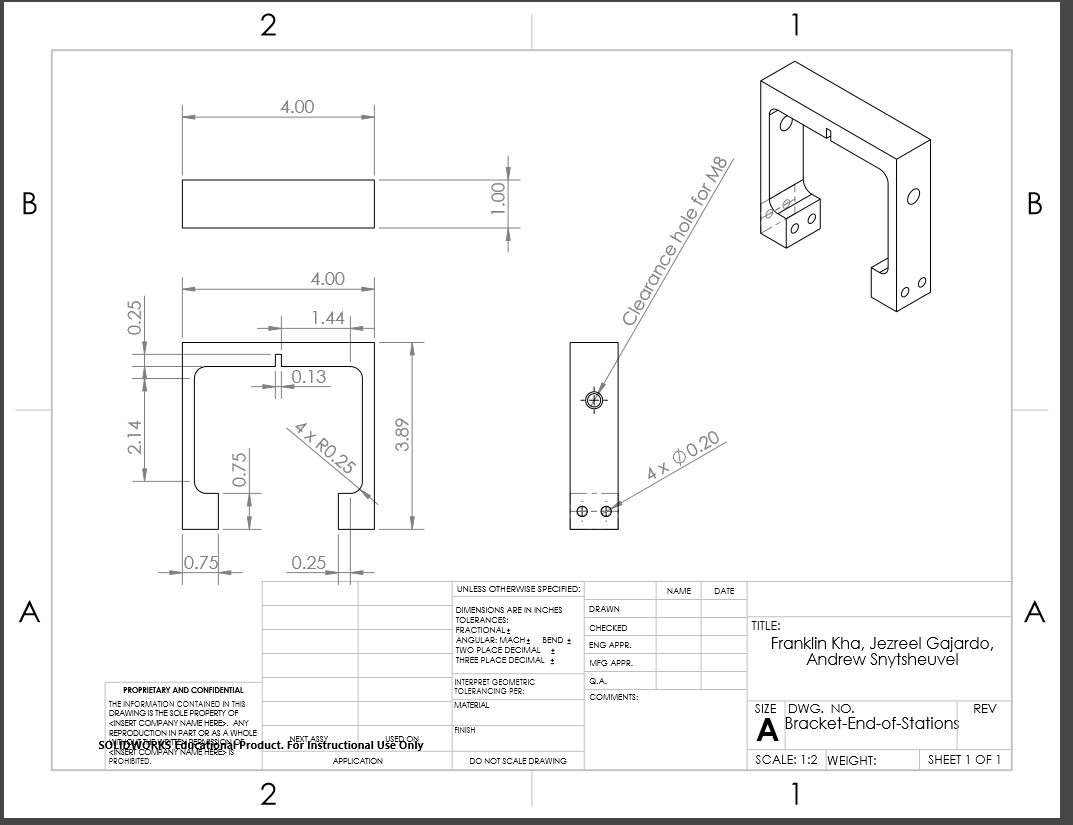

this week I have been remaining in contact with Kearny Foundry and about making a mold for our bracket (picture shown below). The only problem with the mold is that they would be unable to create the press fit and holes of the bracket (which would require for us to machine ourselves). I spoke with Kevin (from the manufacturing team) and we could make a station and/or mount to repeatedly tap holes and make the press fits consistently. Just this morning, however, I finally obtained a quote from them and they said: $940 for the mold and $16.30 per heat treated casting which totals $1429 and would take about four weeks. I told this to the group and we decided that we might just 3D print the brackets instead with a 60% ink fill PLA filament approximating $60 and roughly three weeks. 3D printing would save time, money, and solve the issue of creating repeatable press fits and holes.

No comments:

Post a Comment